One Switch

Along the lines of last weeks’ post about keeping it simple, I want to talk about my brew-day and the simplicity of only having one switch to deal with. This applies to small breweries that are in a tap room or brewpub, not larger production breweries. When I say small, I mean 10 BBL’s or less.

When I had my production brewery - a 20BBL system with 40BBL tanks - it had the large control panel and the manifold with all the butterfly valves on a mono-bloc system. It looked very impressive and was efficient for producing a lot of beer. Cleaning was always a pain in the ass because you have to run a cleaning cycle through each one of those valves, which took forever, but overall I was happy with the system.

In contrast, everyone of my other breweries I’ve owned had a system that was just connected by hoses and one pump on a cart. Hence, the one switch, on the pump.

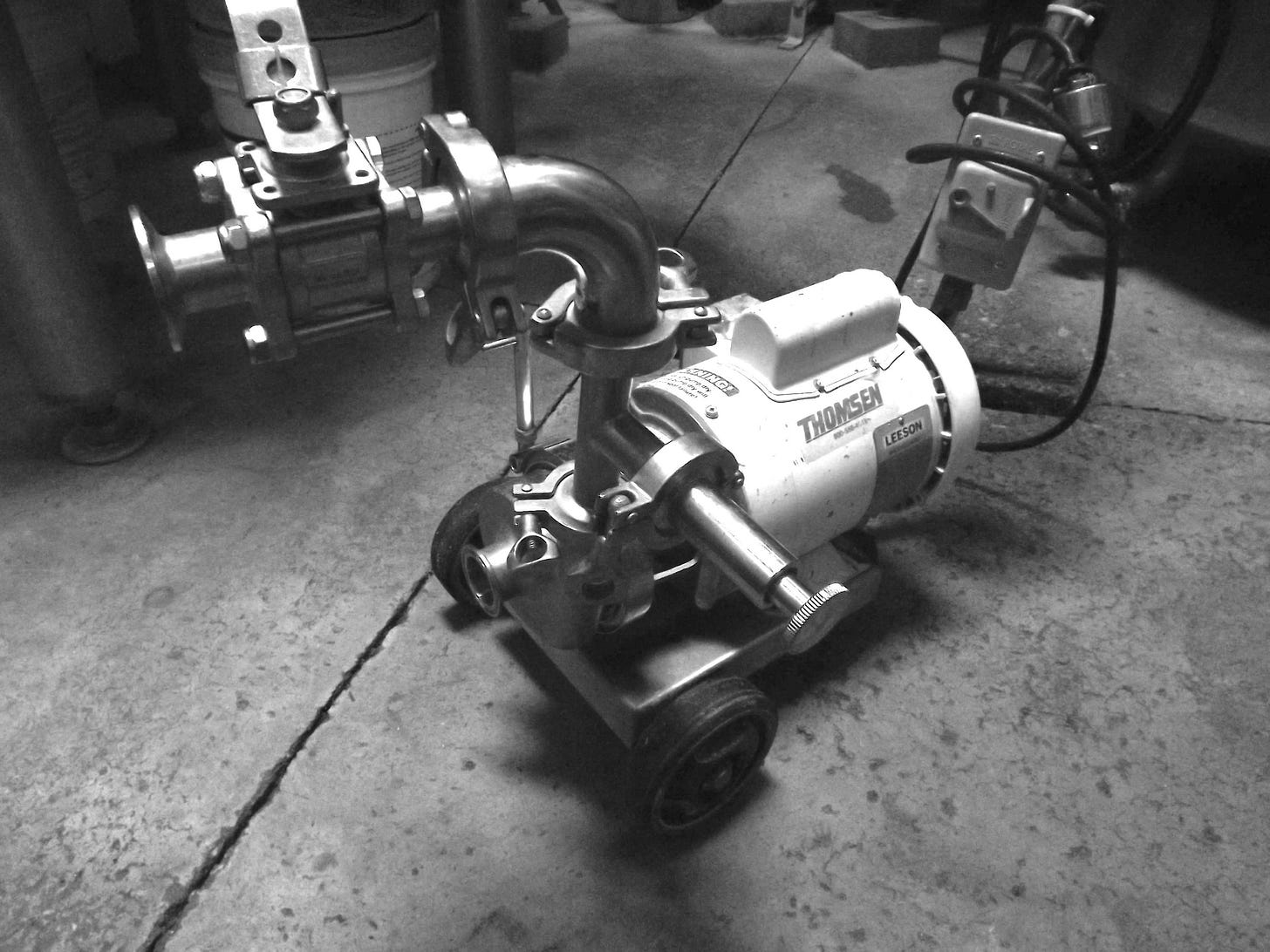

For hoses I need two 6 ft. hot hose sections, and one 8ft. hose section. For transfer hose about the same thing. My pump is a good Thomsen 1 HP pump on a cart with a switch.

The day before the brew I fill the brew kettle with water and heat to almost a boil (here at altitude that is 202 degrees). When I come in the next day, I turn the kettle back on but it hasn’t lost too much heat over night so it gets up to about 170 in the time I get my grain ready at the mill.

Using one short hot hose and one long, I hook the kettle to the mash tun via the pump and start the water. As the water just covers the screens I start the mill and mix the water with the grain through the grist hydrator. Transferring water at 170 gives me a mash of about 153.

Once mashed in, there is still plenty of water left in the kettle, so I turn the kettle back on and heat it to 180. Once the water hits that temperature, I pump it up to the hot liquor tank. This tank is set up higher than the mash tun and is not insulated and there is no heating element in it. As soon as the water is in the tank, I’m ready to use the long hot hose and connect it directly from the hot liquor tank to the sparge arm of the mash tun. I use the two shorter hot hoses to go from the bottom of the mash tun to the pump, then back to the now empty kettle. I hit my one switch to start pumping wort to the kettle - slowly - while I also simply open the valves of the hot liquor tank to sparge. I keep one inch of sparge water on top of the grain bed. This water is now coming out at about 170 degrees. Knowing the volume of liquid in the mash tun with one inch of water on top, I cut the sparge at the right time based on the kettle level so that the rest of the wort flows to the kettle without anymore sparge water diluting it.

There is a better explanation with pictures on all these processes we use to make beer in the book Colorado Boy SOP.

You get the idea. No matter what I am doing with the brew from brew day, to transferring from fermenter to serving tank, to cleaning and sanitizing everything, it only requires two sections of hose and one pump with an on and off switch. My one pump is vital and after every brew I take the head off and clean the seals. We never have a problem with it.

With this set up, you can mix and match equipment which will save you a lot of money. As you’ve probably already noticed, there is a lot of used equipment out there for sale. This is at the heart of how you can put together a decent 7BBL system for 40 to 60k. Just by having one switch.

Actually the sample valve is there to bleed the system. There is always air in the hose, so before we run the pump we can open that valve and bleed the air out of the system. We do also use it if we want to take a sample during a transfer.

On the picture of your pump you posted on the article I noticed you have a sample valve attached to it. I never thought of doing that. Are you using it to take both hot side and cold side samples when transferring?

Thanks!