If I could go back in time, I would have attended refrigeration school. That education would have saved me about $1,000,000,000,000.00, or at least that much in refrigerator repair headaches. You know, the breakdowns that only happen on a weekend, when no one is at your brewery?

My general philosophy is to always buy used except for refrigeration, as it seems to break down more often than anything else. We maintain our refrigeration by keeping the coils free of dust through a weekly cleaning schedule that includes using compressed air to blow out the condenser fan system.

A refrigeration unit for a cold room where you store kegs, cans, or like us, serving tanks, can run in the neighborhood of $3,000 to $6,000. There is an alternative however that I learned about years ago called a Coolbot.

The Coolbot is sold by a company called Store It Cold, and can be bought from places like More Beer.

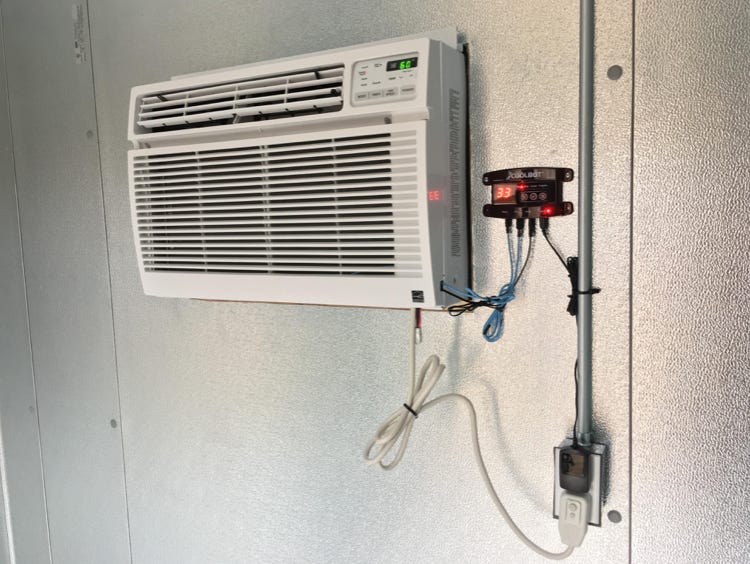

Essentially a Coolbot is a control unit that has a thermostat and a small heating element. You attach the heating element onto the temperature sensor of a typical home-use air conditioner. This ends up using about 40% less electricity than a conventional cooling system.

You set the Coolbot to your desired temperature, say 38 degrees F, and it will send a small amount of power to the heating element attached to the temperature sensor on your air conditioner, fooling it so that it keeps operating. When the room temperature gets to the set point on your Coolbot, it turns off the heating element, and then your air conditioner turns off. Is this viable to use in a brewery setting? Yes and no.

If you are using it to cool a room where employees are often going in and out, the home air-conditioner doesn’t have cooling power to keep up with the door opening and closing. However if you do not go into that room often, it should be fine.

At the Colorado Boy Depot in Ridgway, a Coolbot is used for a ten by ten cooler. We built it by purchasing used walk-in panels that simply toggle onto one another and it took us about two hours to put it together. The cooler is basically the back of the bar, so the beer taps pull beer from the inside of the cooler through the wall to the bar.

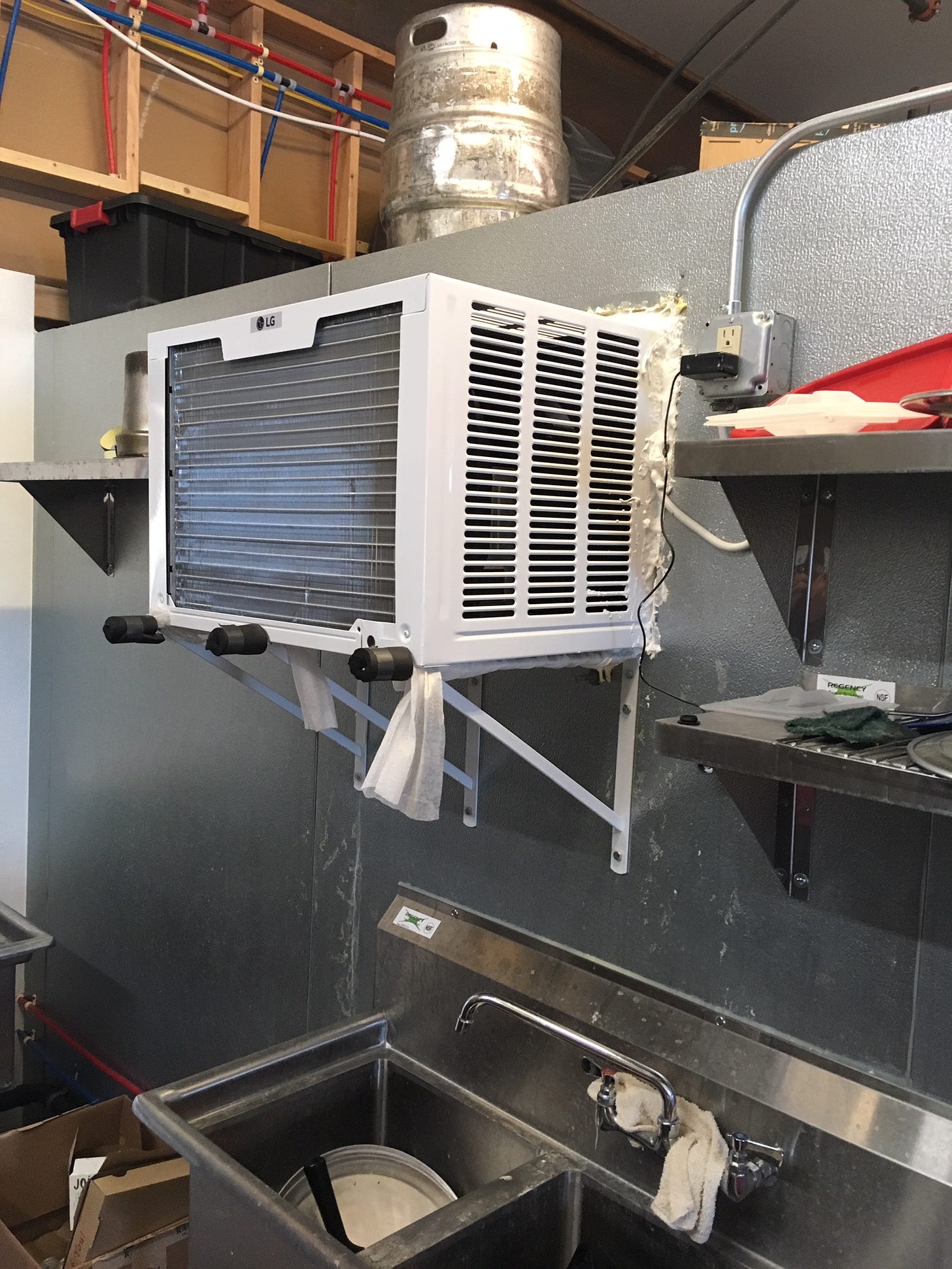

On one side an opening was made to fit a 24k btu home window air-conditioning unit. It just plugs in to a regular 15 amp 115v outlet. The Coolbot can go inside the cooler or outside, so long as the temperature probe and heating element are inside and able to connect to the temperature probe on the air conditioner. It’s very easy to hook this up.

Jake Evans, who brews at Colorado Boy in Ridgway has great experience with the unit. “It does struggle while cleaning with the door cracked open for hoses. But I wouldn't say it takes too long to get the air temp back down after you are able to close the door. Probably 20 to 30 minutes to get back to the low 40's and then within an hour (or less maybe) I feel like the air temp is stable at 39-40.”

At the Montrose Colorado Boy, we have a very small walk in cooler that is only used for storing back up kegs, hops and yeast. The difference with this cooler however is it is sandwiched in between two food coolers, so it was impossible to add a window air-conditioning unit on the side. To get around this, we bought a mini-split cooler. This has the compressor and condenser unit on the roof of the cooler, while the fan with the thermostat is inside the cooler. The Coolbot in Montrose is inside the cooler, controlling the fan and thereby controlling the cooling unit. We have had this arrangement since 2016 with no problems at all.

One new addition with the current generation of Coolbot, is it can be controlled wirelessly from an app on your phone. That way you can monitor the temperature from anywhere.

While I realize this is not for everyone, and maybe not for most who read this newsletter, it is perfect for the start-up small brewery, where saving every penny counts. It has worked for us, so why not at least consider it an option if you are building or expanding?!

9 times out of 10 when you present a cheaper alternative I think it's practical, interesting and useful. Coolbot for a small brewery in warm climates are probably an exception. If as you say it's for a back up cooler it may work, but as a primary cooler it doesn't have the BTUs to handle the constant door opens a taproom cooler will face. I have seen numerous examples in NC of breweries pouring pure foam in Summer months and all of them were using Coolbots. Also the breweries I have seen using them tend to burn through home ac unit and have to replace every 4-6 months. Perhaps we have a unique environment here and as a secondary unit it may be fine, but taproom driven spaces I'd buy from the restaurant auctions a traditional cooler.