When we start one of our one-on-one Brewery Immersion Courses we begin by sitting down to do a deep dive into the student’s brewery project. One of the first topics is how much money the student is prepared to spend on their brewing equipment. A typical answer is around $100,000 and up. This pleases me so, because right away I know I am not only going to save them the cost of their class, but probably tens of thousands of dollars as well. The first big savings is going to be with their glycol system for the brewery. Let me share it with you.

I have had all sorts of professional brewing glycol systems, most of which I bought used for five to ten thousand dollars. They have been great too, but they typically are also energy hogs and take up a lot of space.

When I started the little Colorado Boy in Ridgway, I bought a glycol chiller from a hospital, trying to save some money. The thing was loud and didn’t do a very good job at crashing beer temperatures after fermentation. It was fine for maintaining temperature during the fermentation, but that was about it.

I started thinking about simple glycol chillers used for tap lines. You know, the small ones that chill a trunk line for remote taps. As my loud hospital glycol chiller was starting to fail, I felt there was no time like the present to take a chance and switch to another type of chiller.

I went to Foxx Distributing and bought the largest line chiller they had. It’s a UBC 3/4 HP model, and costs about $1,900. The question was, would it chill my two seven-barrel fermenters? It was worth the risk.

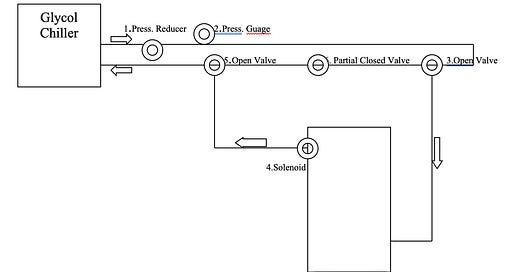

It was delivered in a couple days and I quickly hooked it up. That was easy. It comes with a simple procon pump with an inlet and an outlet, that I hooked onto my existing pipes. For power it only requires a 115v, 20amp circuit.

Switching the chiller on, the first thing I noticed was how quiet it was. Later I would see how my electric bill was less also. So far so good.

The chiller had no trouble maintaining an even temperature on my two fermenters. When I went to crash our Letina (uninsulated) fermenters, the temperature dropped to 36 degrees, no problem, which is plenty for all the yeast to fall out.

Next I tried the Foxx UBC chiller in our Montrose location. There we have two seven-barrel conical fermenters - each have two jackets - and one Letina fermenter. This was the same result; no problem maintaining temperatures on three fermenters and chilling to about 36 degrees. Some of our students have been using the same chiller for four fermenters with the same success. I wouldn’t go beyond that. One thing I will say is don’t try to crash two fermenters at the same time, I’m not sure the chiller can handle it.

Now, is this chiller as good as a chiller designed for a brewery? No way. A proper chiller can not only crash multiple fermenters at the same time, but if sized correctly, can also be used with a two-stage plate heat exchanger to chill water going into the heat exchanger, eliminating the need for a cold liquor tank. You pay for that difference however.

This chiller is perfect for the small seven barrel brewery, where you are watching your pennies. One other thing, it’s built to last. The chiller in Ridgway has been running 24/7 for about ten years. We have replaced the pump and pump motor, also the fan motor. That’s about it. These replacement parts are cheap and Foxx Equipment sells them. I keep a spare pump and pump motor on hand in case it breaks at the wrong time, which seems to be the rule. The expensive part, the compressor, still works like a champ.

Here is one of my super professional videos (made in 2012) demonstrating how to install a glycol system that also shows this chiller. Also you can see how we plumbed the system using simple Home Depot pvc. If I were to do another brewery, I would switch to PEX pipes and fittings, which would be even easier.

Those who work in really nice turn-key breweries will be rolling their eyes at all this, but what can I say. It works.