Building A Small Brewpub - 12

The following is a fictional description of opening a brewpub

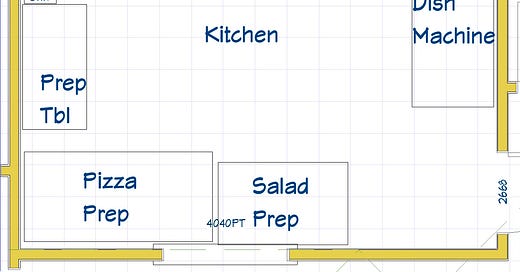

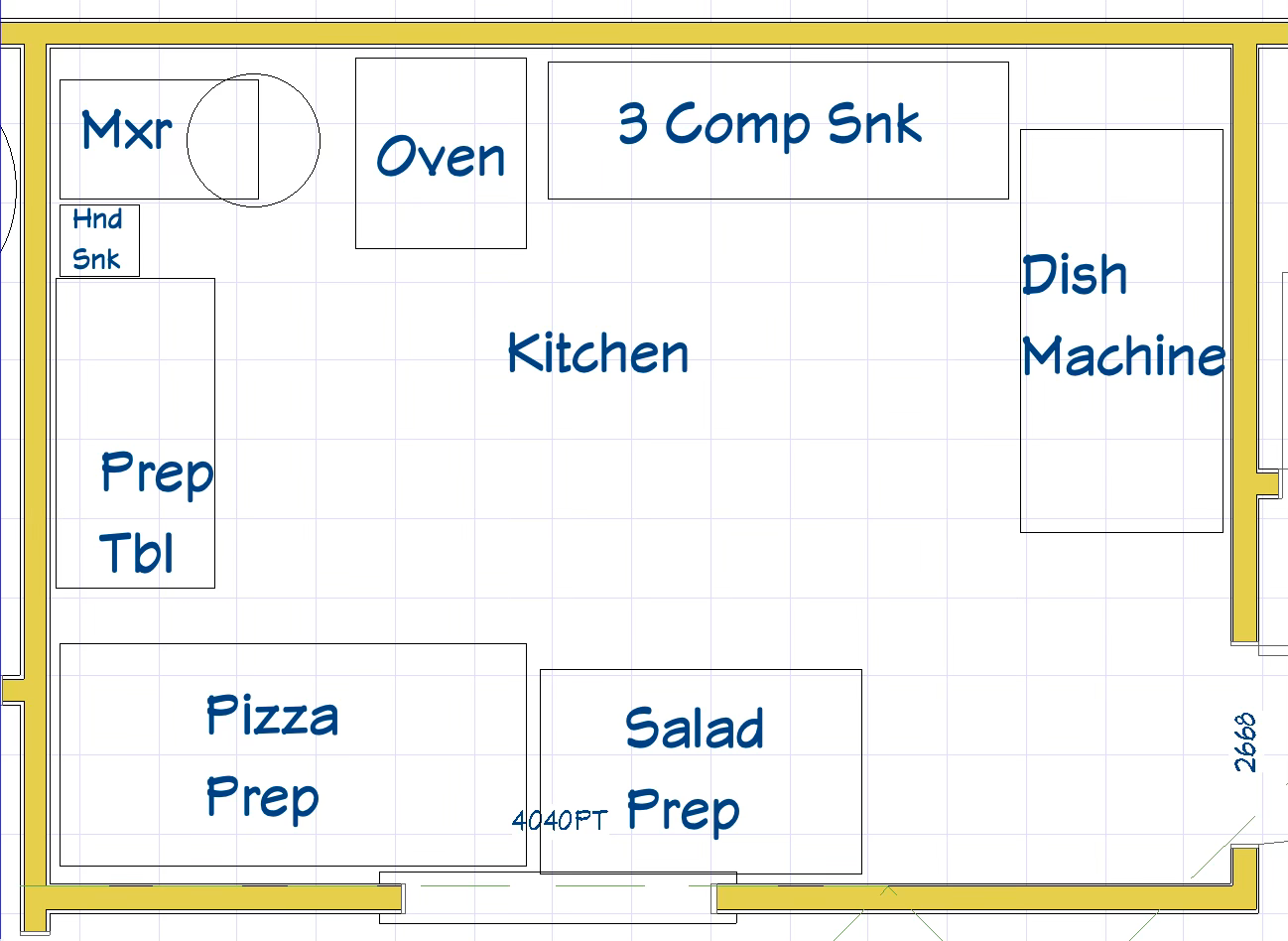

I came up with my simple menu, but I need to get my kitchen equipment next. It’s the most basic kitchen but I figure I can put out a lot of food with it!

Before any kitchen equipment goes in however, I need to make sure the space is ready. This is what the health department wants to see.

Light washable walls. This can be FRP or washable painted walls.

A floor that can easily be cleaned, I am putting down tile.

A floor sink instead of a drain. This looks like a porcelain basin sitting in the floor. It will go under the three-compartment sink. The dish machine, three-compartment sink, and the hand sink will drain into it, but the caveat is the pipes that drain into it must sit above the floor, so that if the sewers ever backed up, it would spill out over the floors instead of up into the drain pipe. This is very important to the health department professionals.

Since there is no gas or open flame in the room, I will install what is called a ‘heat hood’ above the pizza oven. This is just a stainless steel box with a fan to exhaust the heat out of the room. I’ll have to get a heating and ventilation company to install it.

I also need a grease trap for any of the melted cheese or whatever that goes down the waste drain from the dish machine. they said since I have no fryers I didn’t need a large one, and they approved this model that sits on the floor. All dirty water from the dish area flows into it, and any heavier grease gets trapped and just the water continues onto the sewer system. I’ve contracted with a local septic company to come in once a month and suck all the grease out. If I need more I will have them come every other week.

Now for the equipment.

One refrigerated pizza table. These have a wide cutting board where you put the pizzas together. Since I will be doing 11 inch pizzas, I can fit 8 on the board at one time.

Salad prep table. This is like a pizza table but the cutting board isn’t as wide. It will be just to make salads.

Dough Mixer. This is a spiral mixer great for pizza dough.

Dough Divider. I mentioned these before. They are huge time savers. Add about 10.5 pounds of dough in these and if will cut it into 18 - 9 oz. portions

Electric Pizza Oven. This one from Italy is the best, however I could also go with a simple Bakers Pride which has 4 decks and I can fit two pizzas per deck allowing 8 to be baked at one time. I might be able to find one used on eBay.

A three-compartment sink. Each sink has to be big enough for anything in the kitchen to fit in. The idea is one sink for washing, one for rinsing, and one for sanitizing. I plan to use it also as a prep sink to wash lettuce and things in. The health department would rather I have a separate prep sink, but said if I put up a sign saying the sink must be clean and sanitized before using it as a prep sink, we should be ok.

Dish Tables. These go on both sides of the dish machine. The clean side and the dirty side.

Dish machine. I could buy one but I prefer to use a company and rent one. For a nominal monthly price you get the machine and chemicals and a certain amount of racks or cycles. If you go above that many they charge per rack. Most food purveyors have a program to provide you with a machine. Best part is, they take care of it and install it.

A simple hand sink. I like a narrow stainless steel one.

That takes care of the large equipment. In the back of the place I will also have a two-door reach in refrigerator, and a one door freezer.

There will be a long list of small things too. Like an electric hot plate to cook my sauce, knives, spatulas, pizza peels, pizza cutters, dough boxes, rubber mats to stand on, sheet pans, and on and on.

With this ordered, I can now scratch this off my list. But with this simple kitchen, I don’t see any problem making 200 pizzas per night. That’s a lot of food, which means a lot of customers wanting beer. That’s why I’m doing this!

Now on to that beer. I know my water is cold enough for a simple heat exchanger. I checked with the water department and the water temperature never gets above the mid 50’s because it travels below frost level. But when I taste it a get a strong chlorine flavor.

The first thing I did was to boil some water, let it cool and see if I could still taste the chlorine, because regular chlorine should boil off, which would mean I don’t need to filter. But it didn’t.

So I checked with the water department and as I suspected, they don’t treat their water with chlorine but instead use chloramine. It doesn’t burn off. So instead I will have to put in an activated carbon water filter system. It makes no sense to spend all this money on a brewery and then use water that tastes like chlorine. However, that said, my philosophy is to brew with the water you have. It becomes part of your signature. But get rid of the Chlorine taste!

The brewing equipment is in place. My next project is to hook up a glycol system to the fermenters. I’m getting close to where I can do a hot water brew to check out the brewing system.

One more thing. I want to get a microscope, and it has to be a 10x40, just in case I ever want to do gram stains. But really this is for yeast cell counts and viability. So I also need a hemocytometer and counter. As well as some test tubes and of course some methylene blue for viability. I like to place my microscope where customers can see it so they think I’m smart.

It’s been a busy week. Next week even busier!

Sequence of Events

Find a suitable location - check

Draw up a floor plan - check

Check with the town zoning to see if a brewpub is allowed in that location - check

Get someone from the building department to do a walk through in the space while showing them my plan to see if they see any pitfalls - check

Set up Company - check

Set up bank account and fund - check

Draw plumbing plans - check

Draw up detail kitchen plans - check

Meet with architect and engineer - check

Apply for state and federal licenses - check

Come up with a name - check

Get insurance set up - check

Acquire additional funding - check

Sign the lease - check

Demo for plumbing - check

Hire Contractor - check

Start acquiring equipment - in progress

Start on Business System - in progress

Food Menu - check

Service System - to do

POS System - to to

Oyster! - to do

Kitchen Equipment List - check

Bar Equipment List - to do

Order Sign - to do

Order Growlers - to do

Order 32 oz. cans and labels - to do

Build draft system -check

Hook up glycol system

Do hot water brew