Building A Small Brewpub - 10

The following is a fictional description of opening a brewpub.

I’m following the Warren Buffet philosophy of investing. Currently breweries all over the country are closing down which creates great opportunities. Like Mr. Buffet, when people start selling, that’s the time to start buying. Lucky me.

The framing is completed but there are still ways for me to get the brewing equipment in even after we have framed all the walls. Most of the big equipment goes in the garage area and can be wheeled right in. The cooler behind the bar uses a sliding glass door from Home Depot, so that makes it easy to get the Grundy Tanks in there as well.

I’m going to use a Cool Bot and air conditioner to keep the room cold. The people at Store it Cold, who make the Cool Bot hate the idea of using a sliding glass door but I know for a fact that it works. I am thinking the total cost to chill this room will be about $1,000.

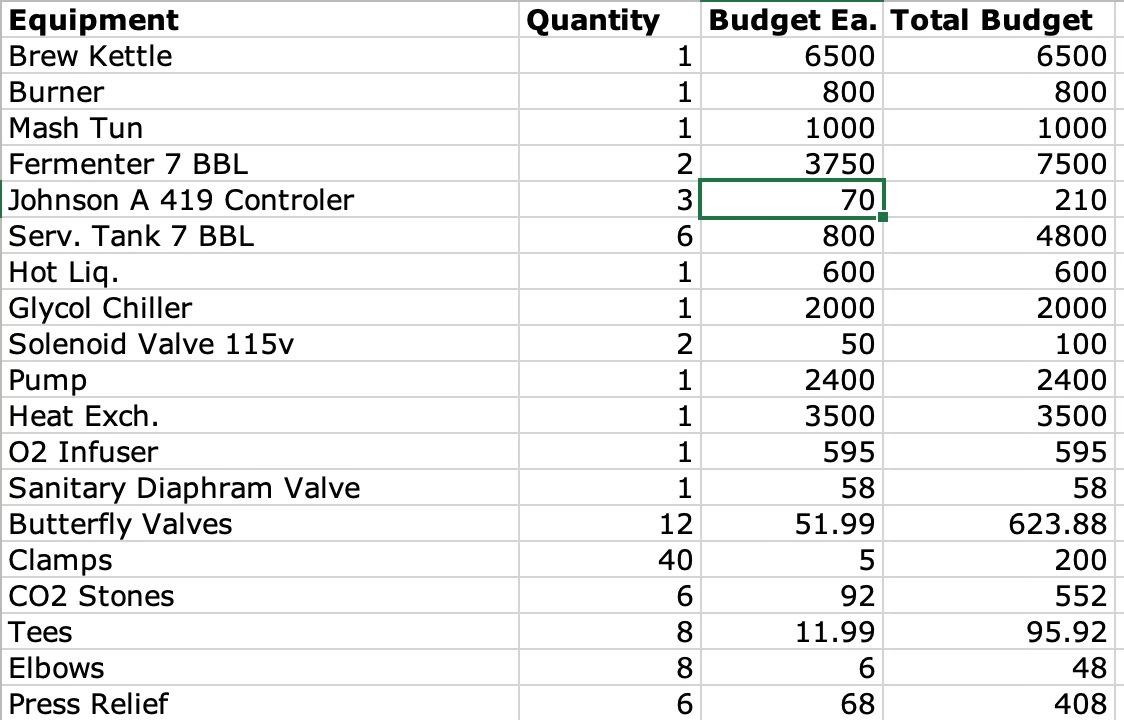

My number one job at this point is to secure the rest of the brewing equipment and I’m 90% there. All the big stuff anyway. Let’s see, I already have my kettle and bought a Midco EC 200 burner for it. I converted one of the $600 Grundy’s into a mash tun by finding someone locally who welds stainless to cut the top off and install a stabilizing ring and making a false bottom using a stainless plate with 3/32 holes in it. I wanted to just use copper pipe but the guy gave me a good price and I will do some of it in trade.

Also within driving distance I found 2 HDP conical fermenters for $3,750 each. I was going to go with a Letina, but they only hold 265 gallons, which means in my experience, anything I brew over 13 Plato I will have to reduce volume or the fermenting wort will blow out the top. These hold just over 300 gallons.

One of the Grundy tanks will be my hot liquor tank, and because I have so much ceiling height, my welder buddy is making a platform that I can set the tank on so that I can gravity the hot water to the mash tun and not need an extra pump.

I went new with a pump on a cart. CPE Systems is pretty reasonable and these are good pumps. There are super innexpensive ones on Amazon from China, but I think, too cheap. I’d hate for a failure in the middle of a brew.

Also from CPE a heat exchanger. As long as my ground water doesn’t go above 70 I don’t need a 2-stage system. Cold water in, Hot wort in, Hot water out (saved to use again in my mash tun) and 70 degree wort out.

Now for some of the small things, I found to my great surprise that Amazon sells a lot of these things much cheaper than the beer supply companies. They are all Chinese but with Amazon (evil empire) you get free shipping.

So so far I’m doing really well on the brewing equipment budget.

Next I’ll get all the small stuff like tri-clamps, gaskets and the things I need to build a draft system.

Sequence of Events

Find a suitable location - check

Draw up a floor plan - check

Check with the town zoning to see if a brewpub is allowed in that location - check

Get someone from the building department to do a walk through in the space while showing them my plan to see if they see any pitfalls - check

Set up Company - check

Set up bank account and fund - check

Draw plumbing plans - check

Draw up detail kitchen plans - check

Meet with architect and engineer - check

Apply for state and federal licenses - check

Come up with a name - check

Get insurance set up - check

Acquire additional funding - check

Sign the lease - check

Demo for plumbing - check

Hire Contractor - check

Start acquiring equipment - in progress

Start on Business System - in progress

Food Menu - in progress

Service System - to do

POS System - to to

Oyster! - to do

Kitchen Equipment List - to do

Bar Equipment List - to do

Order Sign - to do

Order Growlers - to do

Order 32 oz. cans and labels - to do

Build draft system -

For a keg I lift it over. Same if we have to move a tank in, but that's only once. It's really not a big deal.

If using a sliding door, what do you do to get over the door threshold?