Brewery Retrofit Case Study

I thought this would be an interesting exercise for this week. I am helping someone add a brewery to their existing restaurant/coffeehouse and it has had some challenges.

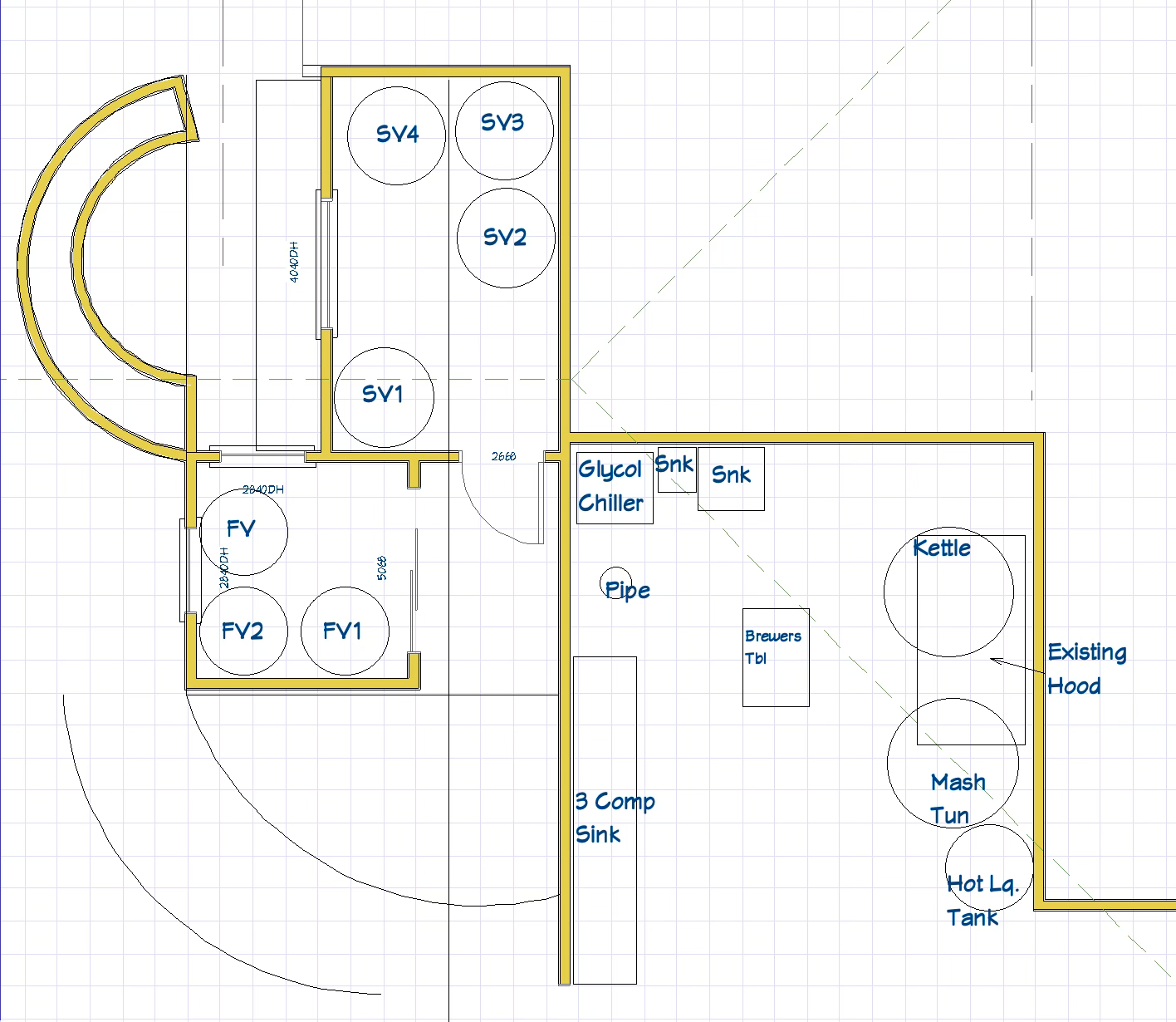

I don’t want to describe their place in too much detail out of privacy, but basically we can use a part of the kitchen, which does have some floor drains and most importantly an exhaust hood with gas to it.

The difficulty is that the ceiling height is only 7 ft. in the kitchen. A plan would be to have a bar on the other side of the wall from the kitchen and a cold room with serving tanks behind the bar so the beer taps can go right through the wall. However there is a balcony running above that wall and that creates a 4 ft. section on the other side of the wall to the kitchen with only 7 ft. height clearance as well.

Most fermenters are higher than 7 ft. so there is no way they can go in the kitchen (and the kitchen isn’t big enough to create a little fermentation room where I could use dairy tanks as open fermenters, as they are only about 4 ft. high).

The only way I could make this work is to place the cooler right under the balcony with room for 4 serving tanks and some kegs. A small room that could hold 3 Letina 1000L fermentation vessels would be just beyond where the balcony would be. I would run 2 tri clamp pipes from the kitchen close to the ceiling to the fermentation room. You use two so you can create a loop for cleaning and sanitizing them. On brew day, you would run your transfer hose from the heat exchanger in the kitchen to the tri clamp pipe and then from the tri clamp pipe in the fermentation room into the fermenter. Not ideal, but workable.

Also, I need a kettle and mash tun that can fit under the existing hood. By using the kitchen hood, it provides an easy method for controlling stream and also flu gases.

On top of this we have a very small budget. To get all this done within budget, two rooms need to be framed out and built. The fermentation room is simple enough but a window should be added so customers can see the shiny tanks. For the cold room, it would also have a window added and use a Coolbot for refrigeration. The Coolbot would cost about $400, and the air conditioner used together with it, would also be about $400.

For the brewing equipment, I found 4 Grundy tanks which are only 40 inches in diameter and about 5 ft. tall. They cost $1,250 each. The fermenters are about $4,000 new and although the room is sized for 3, we could start with just 2. I found a funky kettle that has no top and a burner underneath. It would fit under the hood and being under the hood the steam simply goes up into the air, so there is no condensation falling back into the kettle. The kettle is only $1,500 and sufficient for 7 BBL’s.

Incidentally, I built a kettle like this as a sort of pilot system when I had a large packaging brewery. I used it to make specialty beers just for the tasting room. I brewed two beers that won silver at the World Beer Cup on this system, so you can make a quality product with this.

For the mash tun, a simple round dairy tank would work nicely. There would be no mill, but rather purchase pre-ground malt.

The total cost of the equipment package should run about $33,000, and that includes the glycol chiller, pumps, hoses, everything. Construction depends on if the owner wants floor drains in the fermentation room and cold room, which I would recommend. But to create those 2 rooms is not difficult.

These are great puzzles for my brain.