Ask Dr. Frankenbrew

8/20/23

I received this from alert reader Paulo. He gave me permission to reprint it here.

Hi, Tom

Cost and efficiency wise, which I think is something you cater a lot to, in the spirit of your writings and your target audience, it should be noted that under-pressure CIP of BBT/serving tanks allows for acid cleaning (not talking sanitation with PAA), without having to use heat or clear CO2 from the tank. This will help your bottom line in less energy needed to fight the cold room's temperature raise and CO2 you save by not having to purge the tank again, before filling it with the next batch.

(on a side note, CO2 will absolutely not just flush down the drain when you burst rinse it. It's much lighter than liquid, why would it go out ahead of it? Some will go out, sure, and you can go higher on the caustic concentration to account for CO2 neutralising some of it, but if you are not opening the tank and/or actively venting it with a fresh atmosphere, you will have a CO2 rich environment inside that tank. Risks of tank implosion are real. That it hasn't happened in your 30 years shows you have enough critical thinking to put enough measures in place to avoid it, but that may not be the case with all your readers/followers).

But I think the main point I'd like to raise, again having in mind the affordable brewing perspective you focus on your project, is liner bag serving tanks. Those are a treasure trove to a starting business (where brewing experience may not necessarily be an in-house asset): no CIP needed, cheaper tanks with less armatures and hygienic welding requirements, no premature beer aging if in a poorly purged tank, no energy inefficiency, no CO2 required to push the beer out, and much less man-hour intensive. Liners (in Europe, at least) range from 15 to 25 €, running the gamut of 2.5 to 10HL. It just pays itself over in an heartbeat.

Serving tanks are awesome, I absolutely agree with that! This coming from a brewpub owner in Portugal who chose to spend money where there wasn't much to start with precisely in that.

Best of luck with your endeavours,

Paulo

As a side note: I cover how to clean a tank under pressure in our Colorado Boy SOP. Paulo is right on all of his points, though I have no experience with liner bag serving tanks. Interesting. I had never heard of them, but here is a link that explains.

We carbonate in our serving tanks so with the bag I believe you would carbonate first in your conical fermenter, then transfer (counter pressure) into your server.

Another problem with the bag in my use, is that all my serving tanks are also marked with site glasses so they can be used as Tax Determination Tanks as well as serving tanks. I don’t see how you could do this with the bag.

That said, the bag is so Frankenbrew, that it is intriguing. I’m interested to hear what other people think.

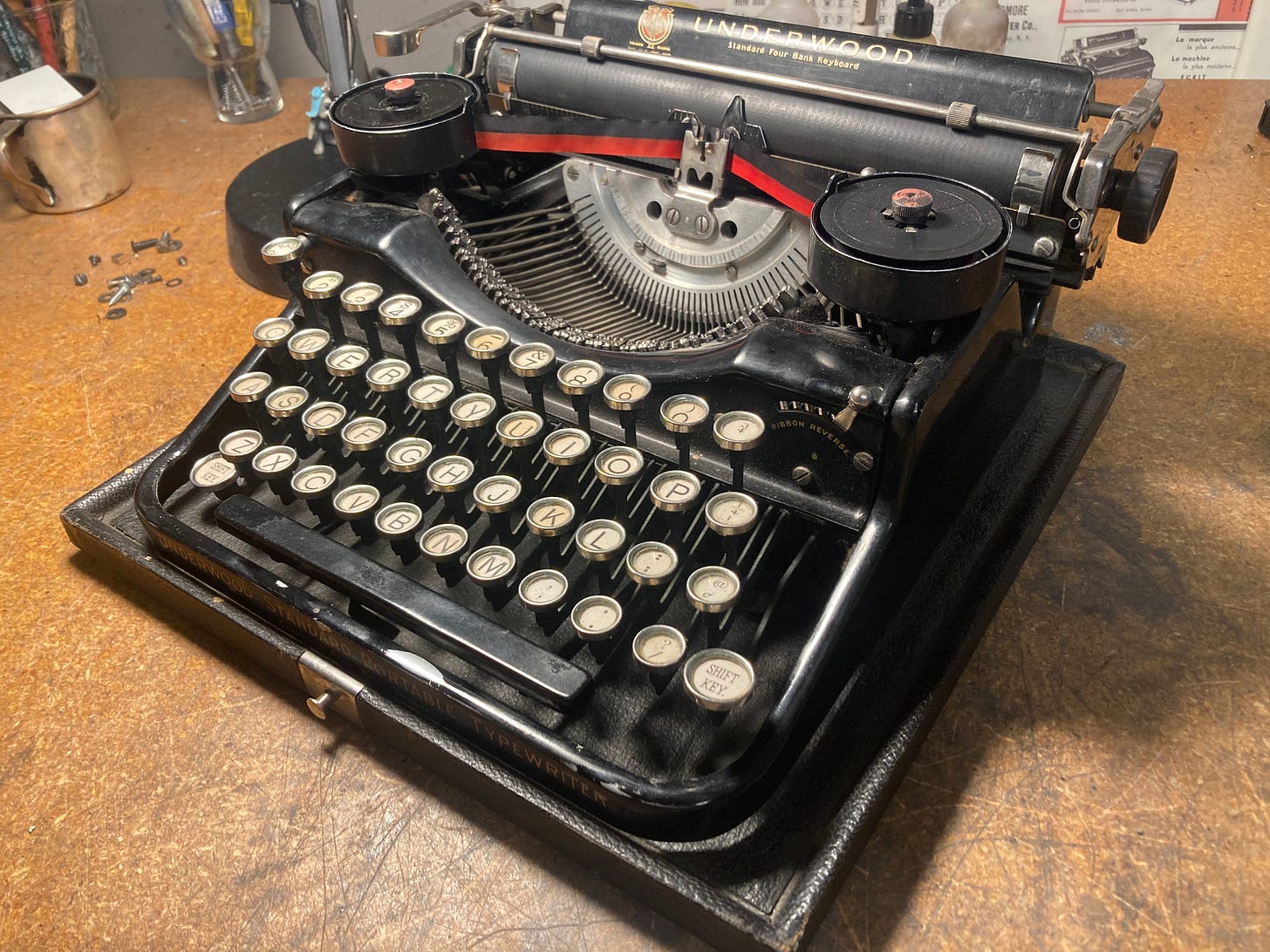

PS, yes I’m a typewriter geek.